Interfaces

High-fidelity electrical interface connections for your ATE

Better electrical interface performance is required to keep pace with more stringent requirements of testing high-performance devices. These improvements also are necessary to minimize yield lost to marginal signal integrity while testing instruments with performance requirements that are becoming more stringent.

Your test results improve when you use the right interface, meticulously designed, properly manufactured and tested.

The InTest EMS Difference

Our PPRs use custom spring modules specially designed to InTest EMS tight specifications for low resistance and mechanical repeatability. Others use off-the-shelf pogo pins.

Our PPRs use custom spring modules specially designed to InTest EMS tight specifications for low resistance and mechanical repeatability. Others use off-the-shelf pogo pins.

High Fidelity and Accuracy

InTest EMS Interface solutions precisely match interface performance to your test requirements

and the conditions where your test will be conducted.

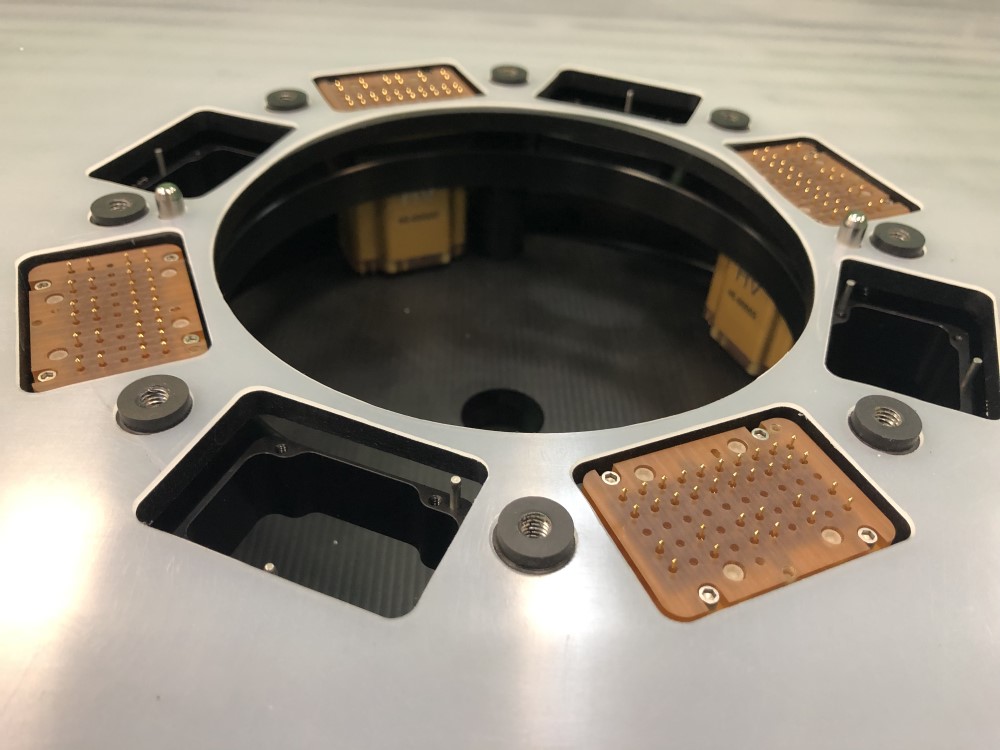

Proven interface solutions for popular ATE platforms that are configurable up to 6,400 pins.

For use on the ETS364/ETS600 testers and many other mixed-signal semiconductor test systems.

The High Power pogo ring has up to 16 modules of 50 probes each. Each probe is rated for up to 5 Amps DC.

inTEST EMS supplies a wide range of hinge mechanisms, adapter rings, ring inserts, and probe card trays for top and bottom loading (automatic card changing) applications.

Engineered for Performance and Reliability

inTEST EMS state-of-the-art designs give you wider bandwidths, lower cross talk, and tightly controlled impedance. Improved durability of interface hardware is required including further improvements in reducing damage to fragile electrical components during normal use, increasing the wear life of mechanical docking hardware, reducing the complexity and the time to repair both electrical and mechanical interface components, etc.

And offering solutions for extreme temperature.

inTEST EMS has products that are specifically designed and manufactured to maintain tolerances and specifications from the very cold (-55°C) to the extremely hot (+200°C) temperatures.

Higher uptime and more consistent results

inTEST EMS Interface solutions deliver world-class precision engineering, unsurpassed MDI (Manipulator, Docking, Interface) integration, and the industry’s best service and support for a full range of applications.

inTEST EMS Interface solutions deliver world-class precision engineering, unsurpassed MDI (Manipulator, Docking, Interface) integration, and the industry’s best service and support for a full range of applications.

Hard Dock Wafer Prober Interfaces

Hard Dock Wafer Prober Interfaces

Cabled Wafer Probing Interfaces

Cabled Wafer Probing Interfaces

Probe Card & PIB Stiffeners

Probe Card & PIB Stiffeners

Test Head Adapters

Test Head Adapters

Test Head Electromechanical Systems

Test Head Electromechanical Systems

Ultra-High Pin Count Interfaces

Ultra-High Pin Count Interfaces