Docking

Better docking solutions for ATE Test Systems

Docking hardware ensures proper alignment and a repeatable dock between the test head and the prober or handler. InTest EMS expertise in system integration has created docking hardware with “plug compatibility,” allowing you to mate otherwise incompatible test heads, probers, and handlers with only minimal changes to peripheral side hardware.

The InTest EMS Difference

The most experienced in the industry. InTest EMS pioneered the multiple cam design decades ago and has perfected it over time. Thousands of units have been shipped and installed on our customers' floors.

The most experienced in the industry. InTest EMS pioneered the multiple cam design decades ago and has perfected it over time. Thousands of units have been shipped and installed on our customers' floors.

With this experience, InTest EMS has standardized customers' docking patterns to ensure docking plates can mate with as many peripherals that exist within a customer's inventory.

With this experience, InTest EMS has standardized customers' docking patterns to ensure docking plates can mate with as many peripherals that exist within a customer's inventory.

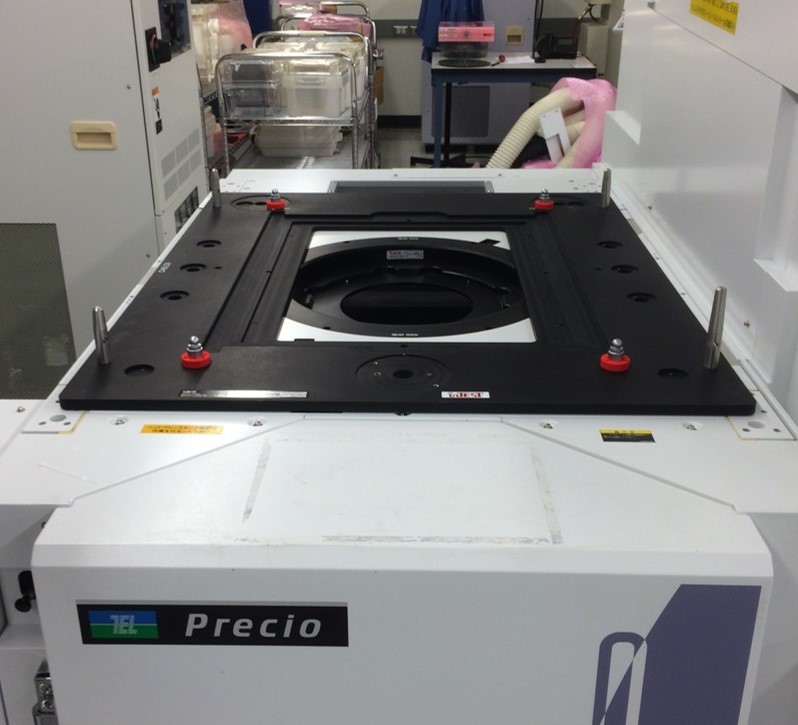

Docking systems to fit your test head set-ups

Pneumatically driven docking system with operator feedback for each step of the docking process..

Consistent, Repeatable Results

InTest EMS Docking Systems securely dock the test head to the prober/handler with accuracies up to 20 um X, Y, and Z. You get maximum consistency and repeatability, test-to-test. We’ve designed and manufactured more than 10,000 docking systems.

Better Docking increases Test Yield

InTest EMS Docking Systems use special high-grade materials that significantly reduce deflection to a minimum, while mitigating mechanical misalignment. With InTest EMS, you’ll increase your OEE with fewer rejects caused by inaccurate, inconsistent setup.

Maximize test floor uptime and ATE utilization

inTEST EMS Docking Systems speed up your test floor with the power of backward compatibility. This lets you dock virtually any brand of test to any prober or handler. This dramatically speeds up changeovers, especially if you run a mix of ATE brands or models.

This advanced design automatically prevents docking action until the units are properly aligned and controls docking depth to keep probers/handlers from damaging the load board. That reduces your test cost through better ATE utilization, improved accuracy, and integrity of test results.

Imagine how much time you’ll save when you can dock all your testers, handlers, and probers without changing docking hardware!