INTELLIDOCK

The InTest EMS INTELLIDOCK is a fully automated docking system that is simple to use and provides operator feedback for each step via a touchscreen display. The intelligent pin and cup design provides real-time feedback of the docking position. Each module cup independently measures the distance the pin is located from the hard stop and provides a method to measure the planarity of the four docking pins relative to each other.

A more efficient way to securely dock a test head to the prober/handler to repeatability within 20 um in X, Y, and Z.

Key Features

Compatible Testers

The INTELLIDOCK docking system can be integrated to communicate with any of the industry-standard testers,

handlers, or probers for an automated docking process.

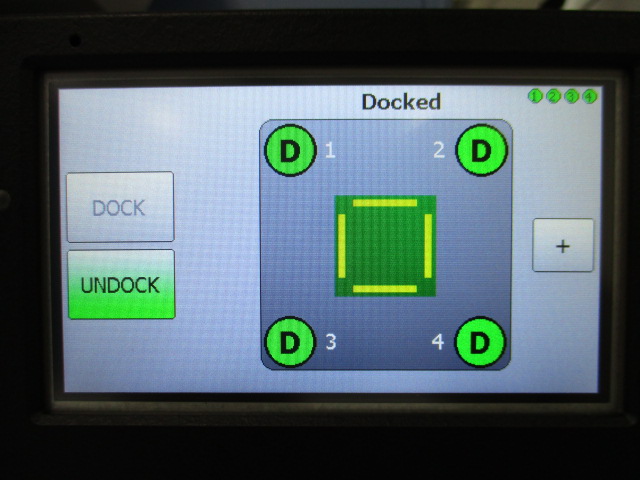

Intelligent Control & Display

The display provides actual docking mechanism position feedback to assure accuracy, planarity, and repeatability. Icon indicators for Undocked, Captured (Pre-Dock), and docked states.

The INTELLIDOCK can be adapted to mount to different test heads, probers, and handlers and is also compatible with InTest EMS designed manipulators and test interface products for seamless MDI (Manipulator, Docking, Interface) integration.

Technical Specifications

Each module and mating pin is pre-aligned to the docking plate. No calibration is required.

| Repeatability | Repeatability in X, Y, and Z axes is +/- 20 um (.0008") |

| Module rating | Each module rated at 115 kg. (250 lbs.) of docking force at 85 PSI/586 kPa |

| Standard 4 point dock | Rated at 450 kgf (1,000 lbf) at 85 PSI/586 kPa |

| High Force 4 point dock | Rated at 680 kgf (1,500 lbf) at 85 PSI/586 kPA |

| Docking pin adjustment | Each pin can be adjusted up to 6.35mm (.25") using the fixed dimension shim kit |

| Facilities Requirements |

Electrical: 110/230 VAC @ 10 Amps CDA: 70-100 PSI @ 1 SCFM *85-100 PSI for full load capacity |